Solder paste: what is it and when do you use it?

Solder paste is a mixture of solder powder and solder flux and is dispensed through a syringe. But why should you use it over solder wire?

What is solder paste?

Solder paste is a mixture of solder powder and solder flux, which are the two components needed to successfully solder together two pieces of metal. In basic terms, solder paste is much like any other form of solder you can buy, but it comes with the advantage of already being combined with flux.

When do you use solder paste?

Solder paste is applied to boards prior to PCB assembly. Its form as a paste provides many advantages and makes the PCB assembly process much easier.

How do you use solder paste?

Solder paste can be applied with a dispenser, which acts like a syringe. This is extremely useful as it allows you to gain pinpoint precision while working with even the smallest of components. Or the most common method of applying solder paste to a PCB is using a stencil printer. For a stencil printer, you will need stencil rolls.

How to apply solder paste

- Before you apply solder paste, be sure the area you’re going to be working on is clean from grime and dirt. Any contaminants can interfere with the process and harm your end product.

- If you’re a first-time user, apply only a small amount of pressure to the syringe at first. This is so you get used to applying the correct force required to deposit just enough solder paste. Putting on too little will result in a weak bond and too much could damage your components and will ultimately go to waste.

- After you have finished applying solder paste, wipe any excess paste away from the end of the dispenser and replace the plastic cap. This will help to maintain the consistency of your solder paste.

How do you solder with solder paste?

Once you have applied your solder paste, apply heat to it in a circular motion that evenly covers all of the metal. If you’re not happy with the bond, you can simply re-clean your components, add more solder paste to the join and reheat again.

Things to keep in mind when using solder paste

- Always apply a little more solder paste than you would use if you were applying solder strip or wire. Remember that solder paste is mixed with flux, so it is not purely solder. The flux will burn away and leave the solder behind, so you need to use enough solder paste to create a strong join.

- You may see the solder start to bubble up during the heating process. This is because the flux will be bubbling as it approaches the annealing temperature. So, don’t worry if this happens - it’s normal!

- Solder paste is advantageous for those small, hard-to-reach areas. But there will be situations where solder strip and wire are better options. Their structural properties mean they will produce a stronger solder joint, so for core components of your piece, you should use solder strips or wires for optimal results.

Ready for the next step?

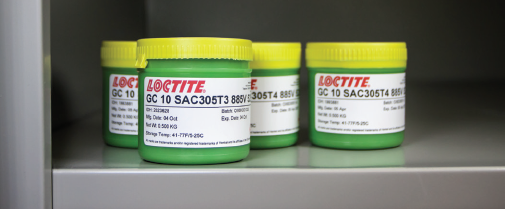

Now that you understand what solder paste is and when you’d need to use it, you’re ready to tackle those tiny spaces that seemed so tricky to reach. Check out our range of Loctite solder paste. Also, see why Loctite’s solder pastes are ‘Game Changers’ or try out Loctite’s solder paste product selector. If you need any further information about solder paste, solder dispensers or soldering in general, feel free to ask our friendly team for advice.